About metal casting: iron casting steel casting riser

About metal casting: iron casting steel casting riser

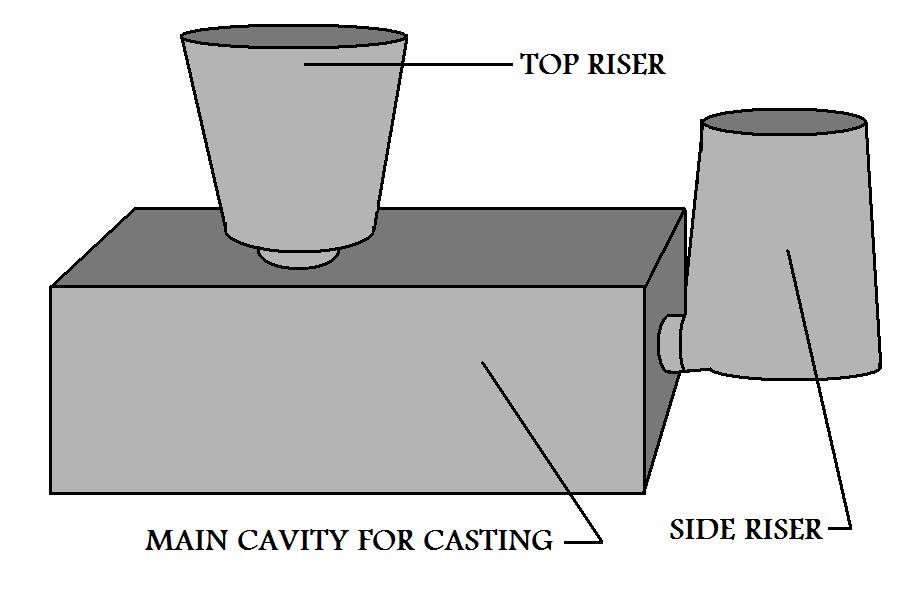

The riser is a reservoir in the mold that serves as a source of liquid metal for the metal casting to compensate for shrinkage during solidification. The riser must be designed to freeze after the main casting in order to satisfy its function. As described earlier, a riser is used in a sand-casting mold to feed liquid metal to the casting during freezing/solidification in order to compensate for solidification shrinkage. To function, the riser must remain molten until after the casting solidifies.

The riser represents waste metal that will be separated from the cast part and re-melted to make subsequent castings. It is desirable for the volume of metal in the riser to be a minimum. Since the geometry of the riser is normally selected to maximize the V/A ratio, this tends to reduce the riser volume as much as possible Risers can be designed in different forms. Risers can be open or blind. An open riser is exposed to the outside at the top surface of the cope. This has the disadvantage of allowing more heat to escape, promoting faster solidification. A blind riser is entirely enclosed within the mold, as in Figure below.