Advantages and Limitations on casting process

Advantages and Limitations of casting process

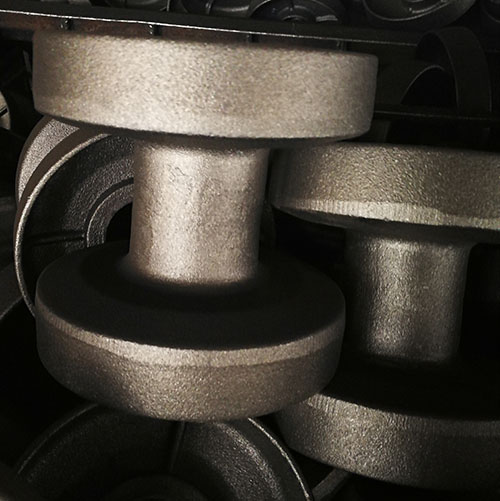

Casting is also known as foundering, is the oldest manufacturing process in which liquid molten metal is poured into a perforated casting cavity of refractory material. Allow liquid metal to solidify, after solidification the casting metal can be taken out by breaking the mold. The casting process is used to produce components such as pistons, mill rolls, wheels, cylinder blocks, liners, machine tool beds.

Advantages of casting process:

Molten metal flows into small ant section in the molten cavity. Hence any complex shape can be easily produced.

Practically any material can be casted.

Ideal method is by producing small quantities

Due to small cooling rate from all directions, the properties of casting are same in all directions.

Any size of casting can be produced up to 200 tons.

Casting is the often cheapest and most direct way of producing a shape with certain desired mechanical properties.

Certain metals and alloys such as highly creep resistant metal-based alloys for gas turbines cannot be worked mechanically and can be cast only.

Heavy equipment like machine leads, ship’s propeller, etc. can be thrown easily in the required size rather than fabricating them by joining several small pieces.

Casting is best suited for composite components requiring different properties in various direction. These are made by incorporating preferable inserts in a casting. For example, aluminum conductors into slots in iron armature for electric motors, wear resistant skins onto shock resistant components.

Limitations of casting process:

With normal sand casting process, the dimensional accuracies and surface finish is less.

Defects are unavoidable.

Sand casting is labor intensive.