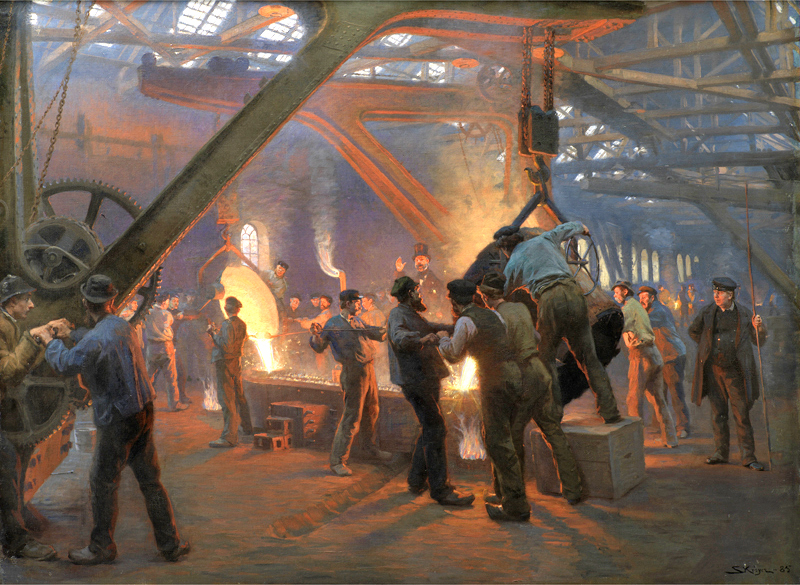

Metal working foundry

A foundry is a factory that produces metal castings. Metals are cast into shapes by melting them into a liquid, pouring the metal in a mold, and removing the mold material or casting after the metal has solidified as it cools. The most common metals processed are aluminium and cast iron. However, other metals, such as bronze, brass, steel, magnesium, and zinc, are also used to produce castings in foundries. In this process, parts of desired shapes and sizes can be formed.

The process includes melting (which performs in furnace), mold making, pouring, shakeout, degating, heat treatment, surface cleaning, finishing.

The final step in the process of casting usually involves grinding, sanding, or machining the component in order to achieve the desired dimensional accuracies, physical shape, and surface finish.

A few foundries provide other services before shipping cast products to their customers. It is common to paint castings to prevent corrosion and improve visual appeal. Some foundries assemble castings into complete machines or sub-assemblies. Other foundries weld multiple castings or wrought metals together to form a finished product.

More and more, finishing processes are being performed by robotic machines, which eliminate the need for a human to physically grind or break parting lines, gating material, or feeders. Machines can reduce risk of injury to workers and lower costs for consumables — while also increasing productivity. They also limit the potential for human error and increase repeatability in the quality of grinding.